Reich Baumaschinen GmbH

Lise-Meitner-Strasse 9

89081 Ulm

Germany

Phone

+49 731 409 866-0

Fax

+49 731 409 866-22

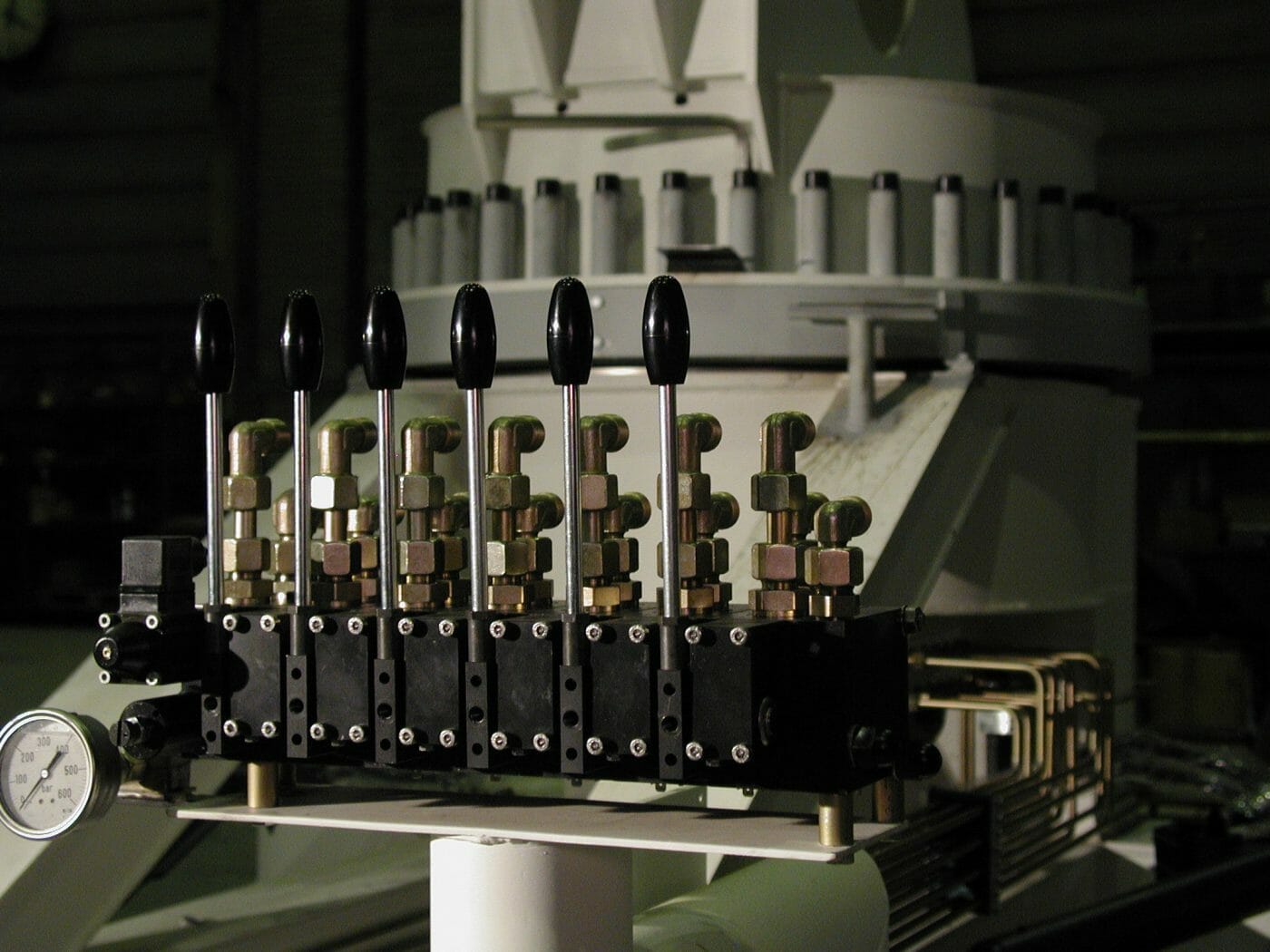

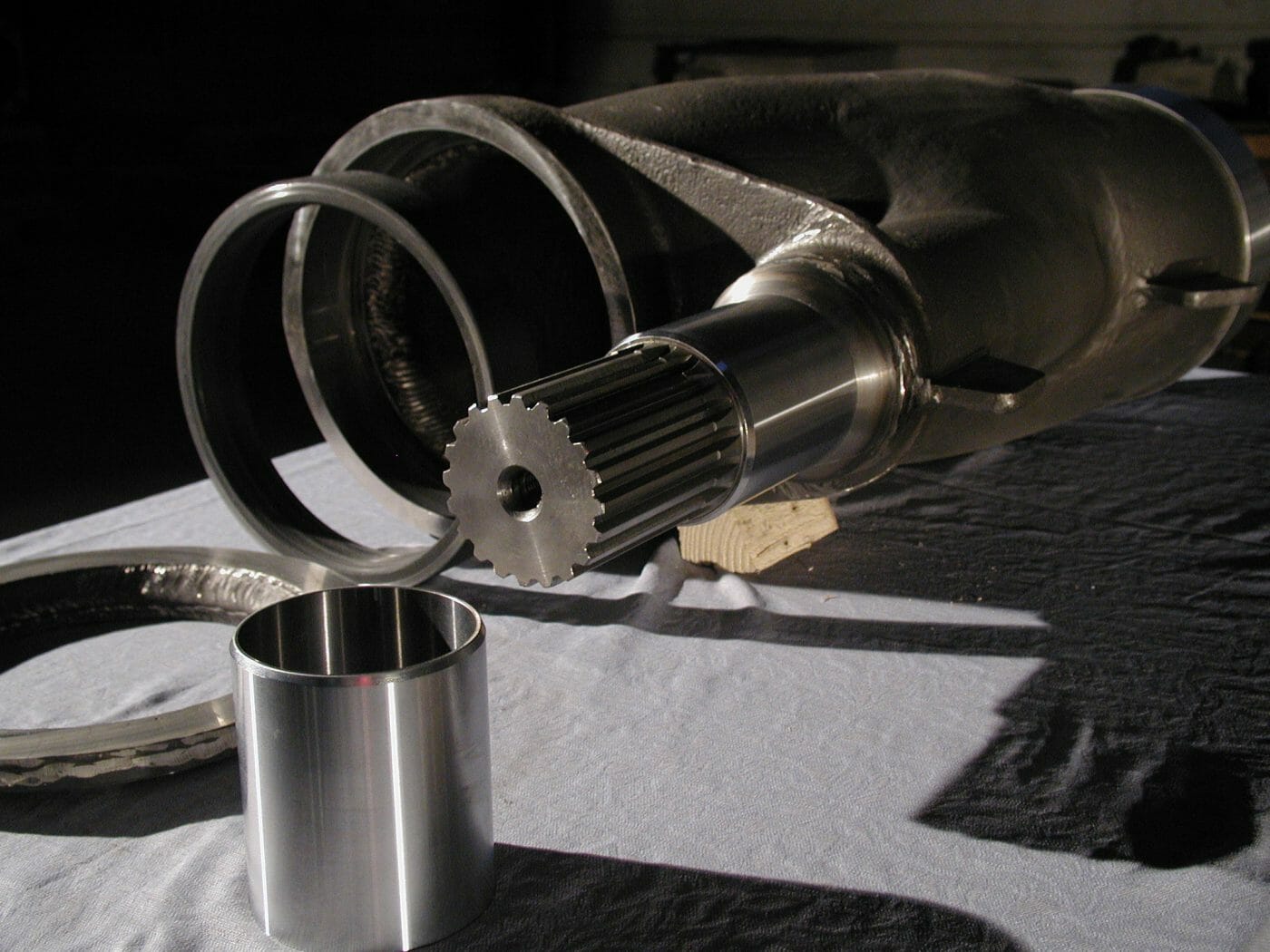

Reich-pumps are made to last in any climate. All Reich pumps are designed to pump virtually any concrete, under any condition. Tough, reliable and sturdy.

Reich pumps are mainly hydraulically driven, thus very service-friendly and easy to run. Reich pumps are produced in Germany, known to be the home of the world´s best manufacturers.

Reich mixing and batching plants are very economical in a number of ways. Sturdy construction, easy access for maintenance and cleaning and a control system taylor-made for each application.

All around the world Reich plants have been earning superior reputation for quality and reliability in most difficult climatic conditions.

Reich truck mixers are among the leading brand world-wide, offering unsurpassed quality and reliability.

Reich is the only manufacturer who developed special mixers for dry loading and on-site mixing offering unsurpassed efficiency and concrete quality.

Reich has been serving the construction market since 1921. In the beginning, Reich was a trading company, but soon turned to manfacturing high-class equipment. From tower cranes to mixers, stationary pumps, truck-mounted pumps, batching- and mixing plants, our products are designed for use in extreme temperatures under the harshest conditions.

Today, Reich is one of the respected players in the global market.

Wherever you come from, you can be sure to get the same high-class technology ideally suited for the most difficult circumstances. Our commitment to international markets dates back many decades and results in long-time customer relations in a large number of countries, backed by local dealers of superior standin

In the beginning, Reich was a trading company, but soon turned to manfacturing high-class equipment. From tower cranes to mixers, stationary pumps, truck-mounted pumps, batching- and mixing plants.

Our products are designed for use in extreme temperatures under the harshest conditions.

Reich Baumaschinen GmbH

Lise-Meitner-Str. 9

89081 Ulm

M info@reichag.com

T +49 731 409 866-0

F +49 731 409 866-22